SEALING & GASKETS

Gaskets are compressible sheets or rings utilized to make a fluid-resistant seal between two surfaces. Gaskets are built to function under extreme temperature and pressures and are available in a wide range of metallic, semi-metallic and non-metallic materials

The primary function of gaskets is to seal the irregularities of each face of the flange so that there will be no leakage of the service fluid from the flange joint.

We supply gaskets from various materials including non-asbestos compressed fibre, rubber sheeting, sponge, and PTFE.

There are three types of gaskets used in process piping.

- Non-Metallic

- Metallic

- Composite

| Non-Metallic | Metallic – Ring Gasket | Composite |

| Compressed Non-Asbestos Fibre Gasket (CNAF) | Oval Ring Gasket | Spiral Wound Gaskets |

| PTFE Gasket | Octagonal Ring Gasket | Camprofile Gaskets |

| Rubber Gasket | Metal Jacketed Gasket |

We supply a range of specialist gaskets including spiral wound, ring joint, grooved /camprofile gaskets, metal jacketed gaskets, non-asbestos fibre sheets and gaskets, rubber & PTFE sealing products.

Proper selection of gasket depends upon the following factors.

- Compatibility of the gasket material with the fluid.

- Ability to withstand the pressure-temperature of the system.

- The service life of the gasket

Flange Insulations Kits:

Flange insulation kits are the most widely used form of controlling losses due to corrosion. They can be used to control stray electric currents in piping at oil, gas, refinery, water, and chemical plants and increase the efficiency of cathodic protection systems and restrict or eliminate electrolytic corrosion.

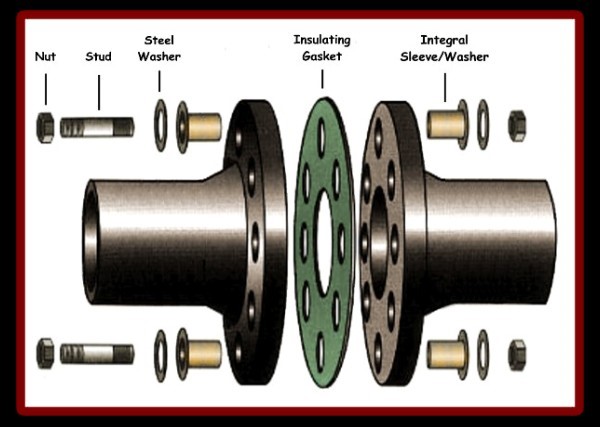

Common components are a gasket, sleeves for bolt protection, and washers for nut protection. The variety of component materials is dependent upon the application.

Insulation Sets offer galvanic protection when two dissimilar flange materials are mated together.

Flange insulation sets are utilized to electrically detach two mating flanges and remove creation of galvanic cell which would lead to corrosion of the flanges and pipework. They are also utilized to prevent the flow of electrostatic charge to reduce/eliminate sparking in dangerous environments which could result in to disastrous situations.

Even where there is no risk of explosion these Insulation Kits are still used to act as a non-conductive interface between the two mating flanges to reduce the potential threat of galvanic corrosion of the pipework in cathodic protection systems.

A typical flange Insulation Kit comprises of.

- 1 Insulating Flange Gasket

- 1 Insulating Sleeve (phenolic/GRE/mylar) per bolt

- 2 Insulating Washers (phenolic/GRE/mylar) per bolt

- 2 Steel Washers per bolt

The components are manufactured from insulation materials with high compressive strength and good stability.

FLANGE ISOLATION KIT TYPES

There are four major types of gasket isolation kits, designated as F, E, D, and O

Type “E” Full Face Isolating Gasket: These gaskets have the identical outside diameter as the flange offering full protection. This will prevent the collection of foreign matter between the flange faces and insures complete cathodic isolation.

Type “F” Raised Face” Isolating Gasket: These gaskets are made to fit inside the bolt circle and protect the raised face portion. It is recommended that a dirt guard be used to prevent foreign matter from shorting out the flanges.

Type “D” Ring Type Joint Gasket: These gaskets are made to fit the ring groove on ring type joint flanges. They are typically manufactured from phenolic based materials, nevertheless customer requirements can be met. It is suggested that the flanges be wrapped or a dirt guard be used to prevent foreign material from shorting out the flanges.

Type “O-Ring Seal” Isolating Gasket: These gaskets use the resilience of an “O” ring to maintain continuous contact with the flange face. Both the gasket and o-ring are accessible in a variety of materials as well as both “E” and “F” styles to suit the requisite.